rubber antioxidant ble powder cas no.6267-02-3/68412-48-6 tanyun

- Classification:Chemical Auxiliary Agent

- Purity:96%

- Type:Rubber additive antioxidant

- Appearance:Light brown or white powder or granule

- Certificate:COA, MSDS, TDS

- Application:Paper Chemicals, Rubber Auxiliary Agents

- Production Capacity:5000 Ton/Tons per Month

- Package:25kg/barrel

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

product parameters executive standard: q/yty003-2011 cas rn: 6267-02-3 1. physical and chemical properties: 1.1 molecular formula: c15h15n 1.2 molecular weight: 209.32 1.3 structure formula: 1.4 density: 1.09 g/cm3 1.5 solubility: soluble in acetone

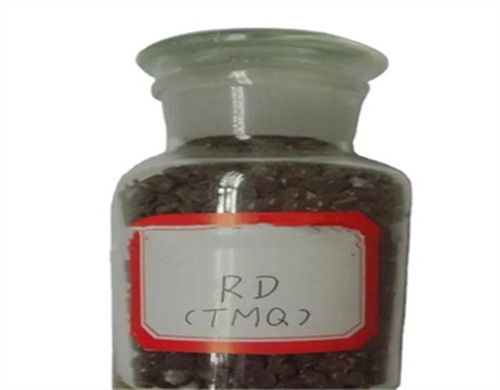

Rubber Chemical Product Antioxidant Tmq/Rd

This product is a pollution antioxidant and a high-performance general antioxidant among amine stabilizers. It has excellent antioxidant, ozone resistance, flex crack resistance, and sunlight crack resistance. It has a strong inhibitory effect on toxic metals such as copper or manganese and is suitable for all types of synthetic rubber and natural rubber.

environmental chemical rubber antioxidants,2.1. amine antioxidants amine antioxidant is the most common rubber antioxidant, which was produced as early as the 1970s and widely used in the rubber industry. typical amine antioxidants include diaryl-secondary amine, acetone-amine condensation product, p-phenylenediamine, and aldehyde-amine condensation product antioxidants [].

rubber antioxidants and their transformation products mdpi

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

growth of ceco-mof in dendritic mesoporous organosilica as highly,doi: 10.1016/j.cclet.2024.109669 corpus id: 267950246 growth of ceco-mof in dendritic mesoporous organosilica as highly efficient antioxidant for enhanced thermal stability of silicone rubber @article{zhu2024growthoc, title={growth of ceco-mof in dendritic.

production and use of typical rubber antioxidants

amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

recent progress in the rubber antioxidants price,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and.

growth of ceco-mof in dendritic mesoporous organosilica as highly

high-efficient rubber antioxidants for enhanced heat resistance without compromising mechanical properties remain an enormous and long-term challenge for the rubber industry. herein, we employed the growth of ce-doped co-metal-organic framework (ceco-mof) in dendritic mesoporous organosilica nanoparticles (dmons@ceco-mof, denoted as dccm) to prepare a novel antioxidant that exhibit outstanding.

The latest development of rubber antioxidants researchgate,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- Which rubber antioxidants are used in China?

- Amine antioxidants are the main rubber antioxidants produced and used in China, of which 6PPD and 2,2,4-Trimethyl-1,2-dihydroquinoline (TMQ, RD) have the highest production, accounting for more than 80% of the total amine antioxidants.

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .