rubber antioxidant 6ppd for tyre, belt

- Classification:Chemical Auxiliary Agent

- Purity:97.%

- Type:Rubber antioxidant

- Appearance:Amber to brown flake or granular

- Place of Origin:Henan, China

- Application:Rubber Industry

- Production Capacity:5000 Ton/Tons per Month

- Package:25kg/barrel

end-of-life tire decontamination from 6ppd and upcycling,abstract. n (1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those.

product name: rubber antioxidant 6ppd cas no.: 793-24-8 mf: c18h24n2 einecs no.: 212-344-0 appearance: dark purple granular.coating auxiliaries,rubber chemicals, plastics, special pigments, flavors and fragrances, food additives, cosmetic raw.

antioxidant 6ppd / 4020 with factory price and good quality

6ppd is an organic chemical widely used as stabilising additive (or antidegradant) in rubbers, such as nr, sbr and br; all of which are common in vehicle tires. [1] although it is an effective antioxidant it is primarily used because of its excellent antiozonant performance. performance.

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

a ubiquitous tire rubber–derived chemical induces acute science

in u.s. pacific northwest coho salmon (oncorhynchus kisutch), stormwater exposure annually causes unexplained acute mortality when adult salmon migrate to urban creeks to reproduce. by investigating this phenomenon, we identified a highly toxic quinone transformation product of n (1,3-dimethylbutyl)- n ′-phenyl-p-phenylenediamine (6ppd), a.

6ppd rubber antioxidant: characteristics, applications, combinations,6ppd (6ppd or n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a widely used rubber antioxidant that plays a vital role in the production of rubber products. this article aims to provide an overview of 6ppd, its characteristics, its applications in rubber product manufacturing, potential product combinations, and important considerations for commercial procurement. 1. what is 6ppd? 6ppd.

transformation products of tire rubber antioxidant 6ppd price

recent evidence indicated the heterogeneous reaction of gas-phase ozone with the precursor of 6ppd-q, a widely adopted tire rubber antioxidant named 6ppd, thus yielding a range of tps including.

environmental fate of tire-rubber related pollutants 6ppd and 6ppd-q: a,abstract. to enhance tire durability, the antioxidant n- (1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine (6ppd) is used in rubber, but it converts into the toxic 6ppd quinone (6ppd-q) when exposed to oxidants like ozone (o 3), causing ecological concerns. this review synthesizes the existing data to assess the transformation, bioavailability.

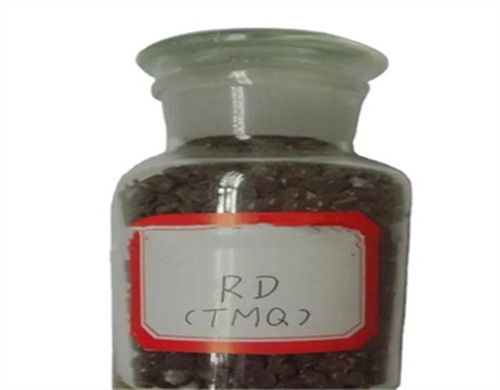

rubber antioxidants tmq particles with best selling

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

screening p-phenylenediamine antioxidants, their transformation,recently, roadway releases of n,n′-substituted p-phenylenediamine (ppd) antioxidants and their transformation products (tps) received significant attention due to the highly toxic 6ppd-quinone. however, the occurrence of ppds and tps in recycled tire rubber products remains uncharacterized. here, we analyzed tire wear particles (twps), recycled rubber doormats, and turf-field crumb rubbers.

- Is 6PPD a toxic oxidant?

- To enhance tire durability, the antioxidant N- (1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine (6PPD) is used in rubber, but it converts into the toxic 6PPD quinone (6PPD-Q) when exposed to oxidants like ozone (O 3), causing ecological concerns.

- Why is Santoflex 6PPD better than IPPD?

- Santoflex™ 6PPD gives better long term fatigue resistance and ozone protection than IPPD. Due to its specific molecular structure and higher rubber solubility, it is less affected by environmental variables, such as heat or leaching, leading to greater durability.

- What causes 6ppd-q in soil and tire rubber wear particles (TRWPS)?

- There is a linkage between 6PPD-Q in soil and tire rubber wear particles (TRWPs), indicating its origin from sources associated with vehicular activities (Klockner et al., 2019). Approximately 50% of TRWPs can infiltrate the soil, releasing bound chemicals like 6PPD (Klockner et al., 2019).

- Why is acetone better than 6PPD?

- Acetone’s lower boiling point (56 °C) compared with 6PPD (260 °C) makes solvent recovery much less energy intensive. Although acetone can readily dissolve many classes of molecules 25, it does not degrade the cross-linked rubber phase. This is crucial for producing a 6PPD-free crumb rubber product that is safe for various applications.